Products

Explore our high-technology products

These products include customized and standard hardware and software, such as automatic equipment identification technology, sensors and nondestructive imaging and security instruments and more.

A-D

-

ACAL® (Advanced Complex Algebra Library) is an out-of-core linear system solution library that uses a hyper-matrix approach to partition large problems.

Benefits

- ACAL allows high computation efficiency when properly tuned for the platform used.

- ACAL performs nearly all vectorizable operations thus, minimizing memory bandwidth requirements. Nearly peak theoretical machine performance for linear system solution can be achieved.

- ACAL can complete symmetric matrices that have been only filled by accumulating entries across the matrix diagonal. For symmetric matrices, this allows a twofold reduction in generation time. It also supports symmetry in the matrix solution process.

Contact Information

Email: [email protected]

-

Leidos led the team that designed and built DARPA’s Anti-Submarine Warfare (ASW) Continuous Trail Unmanned Vessel (ACTUV), now named Sea Hunter, with the goal to develop a highly autonomous unmanned vessel capable of operating over thousands of kilometers on the open seas for months at a time.

-

A proven, high-bandwidth, long-range mobile communications system that overcomes challenges associated with communications on the move.

-

In a contested environment, mission success depends on PNT data that is both accurate and continuously available. Leidos introduces the Assured Data Engine for Positioning and Timing (ADEPT), a resilient software solution to APNT across all domains of battle. "Any platform, any sensor, anytime."

-

Provides automated capabilities, an open architecture, and a standards- based framework necessary to support activity-based intelligence. Capabilities include content management, sensor management, automated fusion, and data integration.

-

ADWS MILES expands force-on-force live training capability and fidelity from infantry-based and armor-based exercises to the inclusion of simulated air defense engagements-ground to air, and air to ground. It provides an adaptable, wireless, tactical engagement and instrumentation system for contemporary air defense weapons manufactured domestically and internationally.

-

ASPS is a digital warehouse of aeronautical source, as well as a collection of services geared toward continual maintenance of that information, enabling on-demand access via the web and NGA Classified Cloud Environment 24/7. It hosts 3.8M source files, all meta-tagged and searchable by numerous criteria. There are currently over 8500 users from NGA, the DOD, State Department, and foreign partners.

-

Our Adaptive Fusion Tracker (AFT) system is a real-time multi-sensor correlation system, designed to perform data fusion and composite tracking across air, ground, and maritime domains.

-

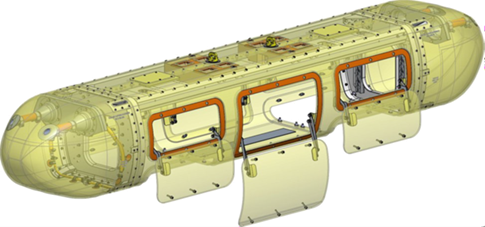

Historically, ISR pods are often designed as a point solution for a specific sensor or suite and are often specific to an aircraft. At Leidos, we know the mission never remains the same. Our uncompromising focus introduces innovative solutions for evolving and accelerating readiness, resilience, and strategic modernization. Leidos has nation-scale expertise, working alongside domestic and international organizations and agencies—including the United States DOD and other government organizations—to revolutionize and future-proof their capabilities around the world and across domains.

Today's threats are evolving faster than our existing platforms, architectures and processes can adapt. The rate of evolution necessitates a scalable, flexible pod system and architecture that can be rapidly reconfigured, tested, and deployed. The AGILEPOD® is the next evolution in pod development providing a podded solution to support tri-service multi-mission capability supporting specialized tactical platforms. The use of a Podded Leidos product combined with Open Systems Architectures provides the foundation for rapid availability and vendor agnostic solutions, leveraging other open standards including, but not limited to OMS, COARPS, MORA, FACE, REDHAWK/TOA, CMOSS, HOST, along with planning, Enterprise IT, and Airborne Integration and Operations to the DOD, Civil, and Commercial manned/unmanned segment.

Contact Information

Steve Santo (Technical)

Email: [email protected]Sean M. Goodwin (Business)

Email: [email protected] -

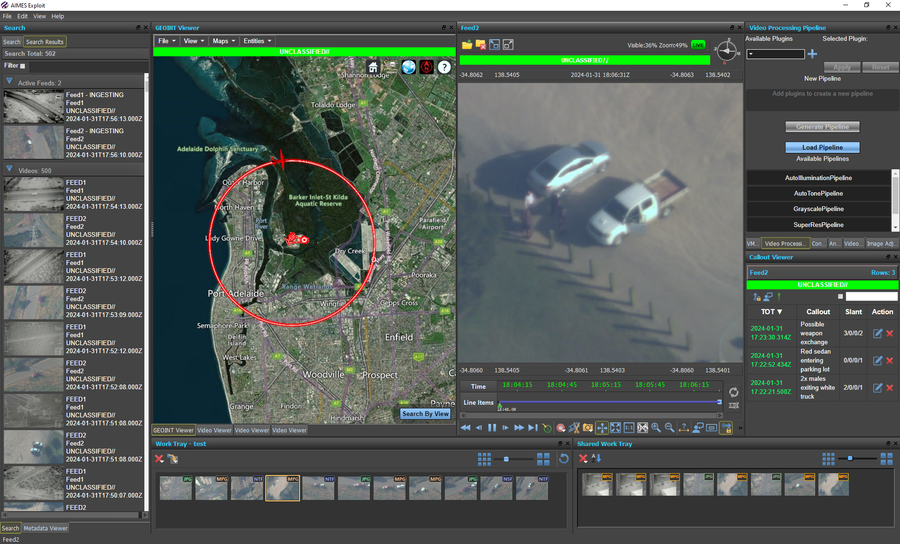

Leidos delivers a Motion Imagery (MI) system that receives, processes, and archives full motion video (FMV) data. Built on a foundation of more than two decades of operational experience, AIMES is both a battle-proven MI solution and a critical enabler for intelligence enterprises. Leidos designed and implemented the AIMES software suite in close alignment with the Motion Imagery Standards Board (MISB) for processing and distribution of MI data.

AIMES 2 is the latest generation MI processing, exploitation, and dissemination (PED) software suite that’s optimized for low bandwidth and high latency networks. AIMES is designed to manage mission tasks in the field or enterprise environment and provide customers with the ability to create rich interactions and highly tailored workflows to adapt to the changing needs of the user.

Applications

- AIMES Server™ software is a data archive element that catalogs, indexes, and stores MISP compliant video slice files from AIMES PICTE. AIMES Server uses metadata contained in the Key Length Value (KLV) PDS of each slice to temporally synchronize the video with additional data available to the Server

- AIMES Exploit™ software is a 64-bit application that provides real-time screening, near-real-time or post-real-time exploitation of imagery and data. AIMES Exploit is able to replay missions via the AIMES Server and able to create, update, read, and delete textual representations of audio callout messages stored in the database. The translated audio callout messages are generated through the use of the AFRL STEPOne client application. Our latest version brings enhanced situational awareness tools to the customer with a new Geospatial Intelligence (GEOINT) Viewer and Video Moving Target Indicator (VMTI) tracking tool. Our new GEOINT Viewer enables third-party Web Map Service (WMS) support, allows users to see tracks, stare-point, and data layers that brings near-real-time (NRT) context to the mission. Our new VMTI tool parses and visualizes MISB 903 object detection data enabling Activity Based Intelligence (ABI) and Structured Observation Management (SOM) analysis and reporting paradigms.

Additional capabilities with AIMES Video Processing Pipeline (VPP) include super-resolution image scaling, video multiplexing, transcoding, data conditioning, and advanced analytical processing that allows dynamic configuration of an end-to-end video processing flow that can be used to transform a stream before rebroadcast, system ingest, or within the end user’s client environment. This approach enables customers to configure their own custom video processing stream that can leverage one or more Leidos or third-party algorithms to rapidly integrate new sensors or analytics - AIMES PICTE™ software captures digital Moving Picture Experts Group (MPEG)-2 Transport Stream (TS) (MPEG-2 TS) transmitted over the network via either unicast (host-to-host) or multicast (one-to-many hosts) User Diagram Protocol (UDP) streams. The video contained in the MPEG-2 TS is compressed using either the MPEG-2 standard (ISO 13818-2) or MPEG-4 Part 10/H.264 (ISO 14496-10) standard. It combines source video data with any associated metadata (extracted from the Closed Captioning data in the video, captured from a separate data source, and/or already contained in a Motion Imagery Standard Profile (MISP) compliant stream) into a MISP compliant MPEG-2 TS with Private Data Stream (PDS). AIMES PICTE will transmit the MISP compliant stream via UDP to exploitation workstations and simultaneously creates MISP compliant video slice files that are sent to AIMES Server for archival. Each AIMES PICTE can support multiple feeds and multiple AIMES PICTEs can also target a single AIMES Server.

- AIMES Restream™ software allows the user to simulate multiple live data feeds of Motion Imagery Standards Profile (MISP) compliant motion imagery transmitted over standard networks via User Data Protocol (UDP)/Internet Protocol (IP) unicast or multicast. AIMES Restream works with existing files formatted as Moving Pictures Experts Group (MPEG) second compression standards for motion imagery (MPEG-2) Transport Streams (TS) (MPEG-2 TS)

- AIMES Reflector™ software allows the user to read and redirect User Datagram Protocol (UDP) or Transmission Control Protocol (TCP) data streams from one Internet Protocol (IP) address/port number to another IP/Port number. AIMES Reflector supports incoming and outgoing unicast, multicast, or broadcast UDP streams and TCP client/server unicast data streams. It gives users the ability to intercept and redirect data (including streaming video) from one IP address/port number to another IP address/port number.

Benefits

- Unlimited number of live feeds

- Real-time playback, recording, and exploitation of multiple live feeds

- Archives data and intelligence products for later use

- H.264 (MPEG-4 Part 10) and H.265 (MPEG-H Part 2)

- HD and 4K support

- MISB 0102, 0601, 0903 and NATO STANAG 4609 standards compliant

- National Imagery Transmissions Format (NITF) output

- Scales from a single site to an entire enterprise

- Virtualization Support

- Experienced on-call support team

- Competitively priced full motion video solution

-

We know important work never stops. Our uncompromising focus is on evolving and accelerating readiness, resilience, and strategic modernization. Leidos has nation-scale expertise, working alongside domestic and international organizations and agencies—including the DOD, DISA, and all branches of the U.S. military—to revolutionize and future-proof their capabilities around the world and across domains.

The AMMP GEOINT SPECTRE is a modified AMMP pod developed to host the SPECTRE sensor. The pod incorporates key features such as inlets and exhausts to maintain sensor thermal management, a linear actuated bay door, machined aluminum strongback, custom mounting lugs, and composite body. While in flight, the AMMP GEOINT SPECTRE holds the SPECTRE sensor, maintains its operating temperature, and allows for sensor line of sight using its sliding bay door.

Contact Information

Steve Santo (Technical)

Email: [email protected]Sean M. Goodwin (Business)

Email: [email protected] -

The Leidos AMPLIFY program investment planning and incentive capture tool provides national accounts, manufacturers, distributors, and contractors with quick and easy access to commercial lighting incentives for a single location or thousands of locations.

-

The AntFarm™ toolkit analyzes the radiation and electromagnetic interference (EMI) effects of single or multiple heterogeneous RF systems. Analysis can be restricted to isolated systems or conducted in situ on the multi system platform.

Contact Information

Email: [email protected]

-

Apatch™ software is an antenna design and analysis tool that provides antenna simulation and modeling by computing the radiation and receiving pattern of an antenna or antenna array installed in an operational environment. The Apatch software can operate on highly realistic, complex, 3D CAD models that are accurate representations of the actual operating environment.

The computer model uses an efficient and high fidelity electromagnetic modeling approach that is based on the shooting and bouncing ray (SBR) technology that is similar to the Xpatch® toolkit. The SBR method launches rays from the antenna(s) and traces them through multiple bounces as they interact with 3D models that define the operating environment. As the rays interact with objects, they deposit currents on the 3D operational environment according to physical optics (PO) principles. These currents are then integrated to generate the scattering contribution of the antenna's environment to produce the overall installed antenna radiation pattern.

Applications

The Apatch software can operate on highly realistic complex CAD models of the actual radiating environment, thereby ensuring a great degree of confidence in the simulation results. Typical applications of the Apatch software include the following:

- Aircraft mounted antennas

- Antennas for ground vehicles and installations

- Impact of radomes: dielectric and Frequency Selective Surfaces (FSS)

- Spacecraft with antennas and other structures

- Spacecraft with antennas and other structures

- Reflector antenna systems

- Ship superstructure interactions

- Antennas on automobiles, trucks, ships, buildings, and mobile handsets

The Apatch software aids engineers in evaluating the interplay between the effects of antenna placement, vehicle geometry, and the surrounding environment. Users of the Apatch software include government organizations and major aerospace firms.

Features

- Observation Angles

- Pattern Re-centering

- Current Sources Antenna Class

- Sub-Array Zoning

- Key Word Input

Benefits

The Apatch software is one of the only codes in the US that supports prediction of the realistic interaction of an antenna with its environment. This modeling capability also provides an invaluable aid in analyzing existing systems and allows the system designer to experiment with various antenna placements to quickly characterize the radiation and coupling performance, thus leading to optimized antenna location. Because our software identifies potential problems with antenna placement prior to testing, expensive cut-and-try design methods can be eliminated, thus significantly reducing design and development cycle times.

Contact Information

Email: [email protected]

-

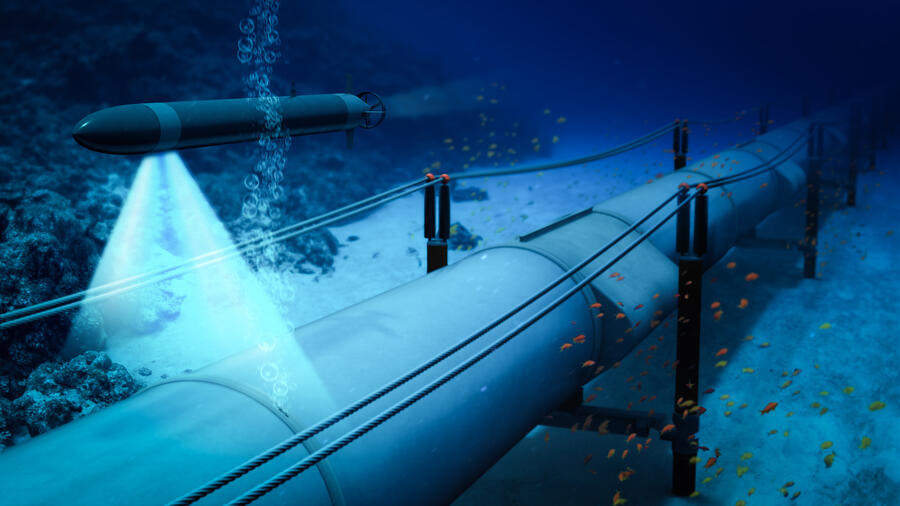

An autonomous robot available for lease from Leidos, for commercial and Government customers to develop new, derivative underwater robotic capabilities and to perform survey and seafloor intervention work currently performed by discrete autonomous underwater vehicles and tethered remotely operated vehicles. ITAR constraints would apply to both commercial and government applications.

-

RPM uses advanced passive scanning technology to detect and locate illicit nuclear material in cargo containers, trucks, and other vehicles in the normal flow of checkpoint traffic.

-

A communications system that supports audio transmission across multiple security domains. MLS streamlines operator workstations with a single microphone headset for use across multiple security enclaves, resulting in seamless mission communications.

-

Leidos' B220 range provides simultaneous detection of explosives and drugs, delivering results in seconds. It performs real-time detection with rapid clear-down and is completely network capable.

-

Bloodhound is a portable, low-profile, high frequency communications geolocation and tracking system. It can be deployed in fewer than four hours and retrieved in fewer than 45 minutes.

Features

- Suitable for tactical operations

- Remotely operated with low SWAP

- Provides coarse, autonomous geolocation estimates in five minutes

-

BTS (Budgeting for Total Signature) is an adaptable threat-based signature reporting tool currently used for radar signatures with planned development for infrared, acoustic, visual, magnetic/pressure, and electromagnetic emissions.

Applications

BTS provides ease in communicating signature budgets in while maintaining controls and visualization that is unique to each signature type.

Features

- Database reports tailored to project’s needs due to true binary database

- Database is developed in Microsoft Access software and engine is written in Visual Basic development system

- GUI pull down menus allow selection of particular signature-dependent degrees of freedom that a designer uses to define a particular scenario (e.g. platform configuration, frequency band, threat, polarization, elevation, sea state, etc.)

- Allows accuracy in signature reporting

- Multiple data processing levels that include specific threat-based algorithms

- Provides succinct output for mission operation analysis

- Allows user to maintain a constant picture of the target/system signature

- Allows real-time adjustments for performing doing what-if scenarios

- Provides a means to mitigate risk through quick isolation of principle signature components

Benefits

- BTS is a user-friendly graphical user interface signature reporting tool for total platform RCS. It lets the user maintain a constant picture of the target/system signature and allows real-time adjustments for performing "what-if" scenarios.

- It has been successfully used across different platforms because the engine for BTS is written in the Visual Basic® development system and incorporates powerful features available in Microsoft® Access software.

Contact Information

Email: [email protected]

-

Circuit Analog STACK (CASTACK™) is a computer code that calculates various electrical properties of a material composed of layers, each of which may contain a regular pattern of arbitrarily shaped circuit elements.

Transmission and reflection coefficients are calculated for the material stack, as well as input impedance, normal layer admittance and layer impedance.

Applications

The CASTACK code is widely used for 1D RF prediction of material design and integration.

Features

- Periodic structures

- Bandwidth optimization

- Sensor integration

- Frequency and angle filters

- Tent Basis Expansion

- Rigorous computation of inter- and intra-layer coupling

- Arbitrary element shape

- Arbitrary impedance

- Arbitrary number of periodic layers and interstitial dielectrics

- Layer characterization

- Anisotropic frequency-dependent shunt impedance associated with each periodic layer - used for termination computations

- Connectivity between elements of the periodic structures using complex impedance materials

Benefits

In the CASTACK code, the scattered fields are obtained by determining the currents induced in the material stack by an incident excitation field.

Contact Information

Email: [email protected]

-

Catena is a real-time supply chain management solution that provides a holistic approach to managing logistics, supplier/vendor information, and data governance. Through dynamic, centralized dashboards, Catena seamlessly integrates and organizes vital data, including supplier information, order updates, and report generation. The platform allows end users and inventory managers to streamline their operations, improve data visibility, enhance security, and reduce costs—while remaining agile in the face of evolving mission demands.

-

A computer code for the radar cross section analysis of objects that exhibit axisymmetric, or rotational, symmetry.

Contact Information

Email: [email protected]

-

SCAP, FIPS 140-2 certifications

-

There are several variations depending on the US NAVY location, and type of water and application. Pearl Harbor uses Dockside Chlorinators (GCI-F-03101); King’s Bay uses Topside Chlorinators AN/TSQ-218 or GCI-F-97127; Chlorinators have also been supplied to Portsmouth, Guam, SubBase San Diego, Norfolk, Connecticut, and the USS ARCO. All chlorinators are designed to prevent biofouling by producing a small amount of sodium hypochlorite from seawater that is injected into the seawater cooling system.

-

Our high-performance ClearScan® cabin baggage security screener uses CT technology and advanced algorithms to deliver the highest level of passenger convenience, allowing for liquids and electronics to be kept in cabin baggage when going through security checkpoints.

-

Leidos developed a product line of virtual individual and crew driver trainers based on a common architecture of hardware and software components. This architecture enables the rapid development and fielding of CDT variants and can be expanded to support a wide variety of international military vehicles.

-

Managed attribution service for bulk and targeted browser collection of Publicly Available Information. DDAM goes beyond non-attribution and misattribution to obscure both the source (proxy server routing) and intent (technical personas and smart fog) of a query.

E-H

-

Software solution with real-time patient flow mapping and logic-based recommendations that enables lean process improvement in hospital Emergency Departments (ED).

-

Effective Medium Theory Materials (EMTM©) is a computer code that calculates the effective permittivity of a material comprising a substrate or matrix that is randomly loaded with general ellipsoidal particles or inclusions.

Applications

EMTM is used on targets that are prolate (fiber-like) and oblate (disk-like) shaped ellipsoids as well as spheres for 1D RCS prediction.

Features

- Controlled dispersion of particles

- Prolates (fiber-like), oblates (disk-like) ellipsoids, multi-layered spheres

- Maxwell-Garnet theory

- Relates external field to internal w/ perturbations caused by inclusions

- Various distributions options

- Simple distribution

- Flat distribution

- Gaussian distribution

Benefits

- EMTM is capable of handling both lossy matrix materials and lossy particles.

- EMTM allows the user to choose various distributions for particle shape such as simple, flat, or Gaussian.

- It automatically checks the validity of the theory used for each case after all data are input.

Contact Information

Email: [email protected]

-

EMTOOLS is a computational electromagnetic (CEM) software suite comprised of 16 different software codes.

-

ACAL® (Advanced Complex Algebra Library) is an out-of-core linear system solution library, using a hyper-matrix approach to partition the problem.

-

AntFarm™ (Antenna Farm) toolkit analyzes the radiation and electromagnetic interference (EMI) effects of single or multiple heterogeneous RF systems.

-

Apatch™ software is an antenna design and analysis tool that provides antenna simulation and modeling by computing the radiation and receiving pattern of an antenna or antenna array installed in an operational environment.

-

BTS (Budgeting for Total Signature) is an adaptable threat-based signature reporting tool currently used for radar signature with planned development for infrared, acoustic, visual, magnetic/pressure, and electromagnetic emissions.

-

CASTACK™ (Circuit Analog STACK) is a computer code that calculates various electrical properties of a material composed of layers, each of which may contain a regular pattern of arbitrarily shaped circuit elements.

-

CATS (Complex Axisymmetric Target Signatures) is a computer code for the radar cross section analysis of objects that exhibit axisymmetric, or rotational, symmetry.

-

CrossFlux is a software tool capable of combining scattering from multiple objects (simulated with separate codes) to form the scattering of the composite target.

-

DUCTSCAT™ is a computer code designed for evaluating the radar cross section of duct geometries with optional material treatments.

-

EMTM™ (Effective Medium Theory Materials) is a computer code that calculates the effective permittivity of a material comprising a substrate or matrix that is randomly loaded with general ellipsoidal particles or inclusions.

-

McCavity is a computer software package designed for evaluating the RCS of cavities.

-

McFSS is a computer software package for the analysis of Frequency Selective Surfaces (FSS). For a wide variety of geometry configurations and material loading, McFSS gives the numerically exact solution of FSS transmission problems.

-

McMoM2D is an electromagnetic computational programs used to calculate the scattering from two-dimensional complex targets.

-

MMADTO™ (Modular Microwave Advanced Design Tool Optimizer) is a 1D, multilayered, laminant absorber design code.

-

SAF is an electromagnetic scattering, radiation, and coupling computational program used to calculate the radar scattering from complex targets.

-

SIG2D™ is a surface integral computer code for radar cross section analysis of objects that exhibit translational symmetry.

-

Urbana™ toolkit simulates wireless propagation and near field radar sensors in complex environments.

Contact Information

Email: [email protected]

-

-

En Route Automation Modernization (ERAM) technology is the heart of NextGen and the pulse of the national airspace system, helping to advance the transition from a ground-based system of air traffic control to a satellite-based system. ERAM provides the foundational platform required for FAA to enable NextGen solutions.

-

Uses passive scanning technology to detect, locate and classify nuclear material in cargo containers, trucks and other vehicles in the normal flow of checkpoint traffic. Automatically distinguishes potential threats from benign material, reducing the need for costly secondary inspections.

-

Our eXaminer Range of enhanced checked baggage screening systems that set the standard for precision, reliability, and advanced operator inspection. The eXaminer's revolutionary multi-slice CT imaging technology generates full 3D imaging for unsurpassed accuracy and outstanding material discrimination, with a choice of footprints, belt speeds to met varying throughput needs.

-

Cloud-hosted, SaaS solution that helps employers enable and automate services related to wellness assessments and flu vaccinations.

-

FuelsManager assists oil companies, defense organizations, airlines and airline service providers with liquid petroleum stock management, asset visibility, accountability and logistical decision making.

-

GSF is designed to efficiently store and exchange information produced by geophysical measurement systems before it has been processed into either vector or raster form.

-

GeoRover software is a flexible, efficient, and standardized suite of geographic information system (GIS) products to aid in the production and analysis of geospatial intelligence. GeoRover products enhance Environmental Systems Research Institute (Esri®)-based technology providing improved data management.

Applications

- 2D/3D GIS Support

- Data Import

- Field Data Collection &

Visualization - Raster Image Display & Data Management

- Data Creation / Editing

- Data Export

- Dynamic Feedback

- Process Automation

Benefits

- Software Add-Ins designed for seamless integration into ArcGIS Pro component of Esri® ArcGIS® Desktop software

- Software Extensions tightly integrated with ArcMap component of Esri® ArcGIS® Desktop software

- Ability to process 3D data, such as Z values or elevation data, in geospatial data with greater ease and efficiency

- Significant reduction in training requirements for ArcGIS

- Increased user confidence, greater acceptance of powerful ArcGIS

- Faster, more flexible interface for ArcGIS Pro and ArcMap

- Improved support for ingestion of data into ArcGIS Pro and ArcMap

- Rapid export of GIS data into standard product formats

- Superior management and display of large RPF file-based datasets (ECRG, CADRG, and CIB)

- Field data collection requires no proprietary hardware, works with equipment already in use

- Built-in licensing mechanism removes additional post-install configuration requirements in ArcGIS Pro

-

The GLIMPS provides accurate, global forecasts on defined lead times of up to five years, focused on turbulent and complex environments, in order to provide the information needed to adapt to changing needs and resources. GLIMPS technology forecasts the effects of poverty, environmental degradation, political instability, and social tensions through big-data mining and machine learning of millions of open-source intelligence data points to discover the unseen relationships between indicators of stress and locations of potential instability.

-

The H15E is a handheld explosives and narcotics detector that rapidly detects and identifies trace amounts of a wide variety of military, commercial, and homemade explosives and narcotics.

-

Features

- No “Boots on the ground” – Using detailed analytic products and big data collection technology we provide local intelligence prior to arrival.

- Impact of “Boots on the ground” collection – We monitor social network change and corruption of collection environments to ID reliable sources with real network influence.

- Inability to identify changing populace sentiment – Our 24/7 automated sentiment monitoring, with predictive analysis provides early threat warning, or continuous evaluation/reporting of MISO results.

- Inadequate HUMINT in denied areas, or areas without adequate IC sources – Our in-country expert network of local personnel in business and government provide immediate insight from multiple levels.

- Searches being attributed back to your organization – Use of full non-attribution systems during collection protect against compromise of attribution back to the source.

- Keeping up with automation and software changes for OSINT collection – We maintain toolset currency, including big data tools, non-attribution, and relationships with niche subcontractors.

- Intelligence Oversight – All our analysts are IO trained and all products with US persons are prominently marked to aid retention and dissemination decisions, ensuring issue-free IO.

- Lack of ability to quickly lift and shift collection and analysis focus globally – Fully scalable with linguist analysts to focus on customer areas, without affecting standing requirements.

I-P

-

As container-inspection technology advances, security authorities need to manage increasing amounts of information from non-intrusive inspection (NII) systems, radiation-detection systems, and other sources — all without impeding the flow of traffic. ICIS brings it all together. ICIS is a powerful hardware and software suite that integrates images and data from VACIS® NII systems, radiation portal monitors and other sources, and delivers it to users on demand, in real time.

-

Incident Command Tool for Drinking Water Protection (ICWater), software was developed by Dr. William Samuels and his team at Leidos. The model predicts when and to what extent contamination will reach drinking supplies further downstream, enabling officials to determine in real time when and for how long to shut off their cities' drinking water intakes.

-

The Leidos Identification as a Service platform, commercially available as IDHaystack℠, provides a biometric matching service that can serve as the core for any identification or verification system.

IDHaystack℠ provides on-demand, pay-as-you-go identification and verification services, all while reducing costs and increasing flexibility. As an integrated suite of reproducible sets of hardware and software, this turnkey cloud solution is designed to be deployed within any cloud environment or within a traditional networked client datacenter, and will provide a one-of-a-kind biometric transaction service.

-

Industrial Defender Automation Systems Manager (ASM) is a management platform that aggregates event and state data from industrial endpoints across all vendor systems in one location for a single, unified view of operations.

-

Leidos In3Sight platform has achieved FedRAMP authorization from the Federal Risk and Authorization Management Program (FedRAMP) Program Management Office (PMO), along with Authority to Operate (ATO) letters from federal agencies. Engaging the services of a FedRAMP authorized Cloud Service Provider (CSP) gives federal agencies confidence to securely use CSP platforms for monitoring and managed services. This authorization indicates that Leidos has developed and maintains a secure cloud solution that will help our customers meet their mission critical needs.

Leidos has achieved FedRAMP authorization for eight consecutive years with experience in the federal and commercial markets. Our continued commitment to security is critical as government customers transition from traditionally owned and operated IT infrastructure to cloud and change their IT service delivery models to “as a service”.

-

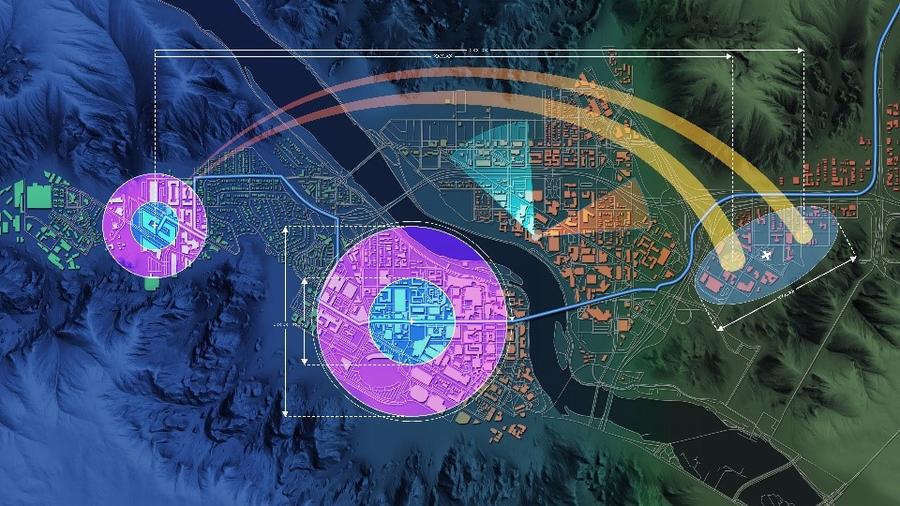

INSSITE is a sensor scene modeling and analysis environment. Different sensor types and modalities, spanning radar (synthetic aperture radar [SAR], ground moving target indicator [GMTI], detection and ranging, radio frequency [RF] communications), visible/infrared (passive electro-optical/infrared [EO/IR], laser radar [ladar], thermal IR), can be evaluated against high fidelity scenarios constructed by the user. Scene models can be constructed using standard Geographic Information System and computer-aided design (CAD) data formats.

Contact Information

Email: [email protected]

-

ISS-2000 was designed for professional hydrographers and surveyors. The compact and powerful ISS-2000 system supports a broad range of high-performance, shallow-water survey operations.

-

IXQ is an automated collaboration tool that allows warfighters and analysts to rapidly obtain critical expertise across the intelligence community. IXQ harvests analytic activity data from intelligence production systems to form a high-fidelity profile of the unique skillsets and expertise of each analyst. Users can then search, discover, geospatially visualize, and connect with peers using the same temporal, geospatial, or contextual queries they might employ for products or reports. Warfighters and analysts use dynamically created, secure collaboration rooms to discuss their objective or problem set, with the capability to post files and links in addition to text. IXQ provides analysts and tactical customers with an unparalleled ability to rapidly discover and leverage subject matter expertise.

-

The Integrated Wide Area Surveillance System (IWASS) is an intelligence-based operational solution for border security. Safeguarding the homeland requires a solution that provides an automated, wide-area surveillance capability to predict, deter, detect, track, identify, classify, respond to and resolve incursions. In addition, this solution provides enhanced situational awareness for force protection, critical asset and infrastructure, and special event security.

Applications

For more than 20 years, Leidos has been at the forefront of solutions that meet the challenges of the border security missions of customs and border protection. In the last five years, we have supported approximately 70 programs with a combined value of more than $200 million.

IWASS is a ready-to-use commercial off-the-shelf system that has been tested in the field and is ready to deploy, providing uninterrupted surveillance within a prescribed area of coverage. IWASS is a turnkey solution that is an open system, standards-based for integration with other technologies. It is also scalable to provide effective coverage as needs.

Features

Leidos border protection solutions are geared to meet specific border security mission needs, now and in the future. We have more than 50 products and applications that can comprise an end-to-end border security solution from prediction to resolution. Our solutions cover the entire security spectrum - from unmanned vehicles, safety and security, and software/hardware to transportation, simulation, and geospatial applications.

Benefits

- A ready-to-use independently tested system

- Open standards allow for technology upgrades and customer enhancements as requirements evolve

- Easy to use

- Low operational cost, no carbon footprint, and no down time due to power outages

- Our solution simplifies deployment and provides options for fixed and mobile applications because there is no additional communications building required

-

Leidos provides pilot proficiency and currency flight training services for qualified Bombardier 6000/6500 type certified aviators as a commercial service. Leidos will provide qualified FAA-certified flight instructors and pilots-in-command (PC) to provide instruction to the customer’s student pilots on Leidos-provided Bombardier Global 6000/6500 jets. Customer’s student pilots shall already be FAA type certified on the Bombardier Global 6000 or Bombardier Global 6500 aircraft. Leidos’ pilot-led, hands-on jet training service will advance the customer’s student pilot in basic and advanced flight procedures and help prepare them to operate a Bombardier Global 6000/6500 aircraft. Leidos’ training includes refresher ground course work to ensure the student pilot is current and familiar with the Global 6000/6500 airframe. Leidos flight instructors and Leidos PCs will conduct currency and proficiency training focusing on the student. Leidos will provide up to 150 flight hours of instruction per a 30-day period.

Contact Information

David Radcliffe (Technical)

Email: [email protected]Sean M. Goodwin (Business)

Email: [email protected] -

Large Amplitude Motion Program is a computer program that calculates forces and tensions placed on an ocean structure by sea conditions.

-

Software platform designed to reduce development time while increasing interaction with the warfighter. As an open framework, it allows for integration with third-party applications, including support for disconnected, intermittent, and low bandwidth (DIL) environments.

-

LPM is a portal solution with a focus on SLA management: it can work with Remedy or ServiceNow to efficiently handle and report on Service Level Agreement (SLA) information regardless of source or complexity. LPM also has data management tools to ensure that all SLAs from the very beginning of a program via reports and dashboards.

-

From seafloor to cyberspace, Leidos delivers advantage that helps our customers succeed at their critical missions. Our uncompromising focus is on innovative solutions which make the sum greater than its parts. We have nation-scale expertise, working alongside domestic and international organizations and agencies—including the DOD, DISA, all branches of the U.S. military, UK MOD and UK NATS. We revolutionize and future-proof capabilities around the world and across domains.

Leidos delivers a holistic Contractor Owned Contractor Operated (COCO) service that includes aircraft, flight operations, maintenance operations, and logistics support. Our multi-mission capability is built on a commercial Beechcraft King Air B300 Super King Air 350 aircraft with the Avcon Industries Multi-Mission POD. We have designed, modified, integrated, tested, and certified the aircraft and all associated support equipment specifically for conducting a wide range of CONUS and OCONUS airborne missions, from aerial survey; wildfire mapping; rapid integration, test, and evaluation; and intelligence, surveillance, and reconnaissance (ISR). The aircraft is able to support a wide range of missions with operating characteristics of cruising speeds at 300 knots and collection speeds at 200 knots, a ceiling of 35K feet MSL, endurance exceeding 5 hours and range of over 1,250 nautical miles. Leidos has recruited, trained, and certified a complete aviation staff capable of conducting worldwide self-deployable/self-sustainable operations from civil and military airfields without any special or unique support equipment.

Contact Information

- David Radcliffe (Technical) Email: [email protected]

- Sean M. Goodwin (Business) Email: [email protected]

-

At Leidos, we know important work never stops. Our uncompromising focus is on evolving and accelerating readiness, resilience, and strategic modernization. Leidos has nation-scale expertise, working alongside domestic and international organizations and agencies—including the DOD, DISA, and all branches of the U.S. military—to revolutionize and future-proof their capabilities around the world and across domains.

Leidos delivers a holistic Contractor Owned Contractor Operated (COCO) service that includes aircraft, maintenance operations, and logistics support. Our Aerial Survey capability is built on a commercial Beechcraft King Air 350 aircraft. We have designed, modified, integrated, tested, and certified the aircraft and all associated support equipment specifically for conducting a wide range of CONUS and OCONUS Aerial Survey missions. The aircraft is able to support a wide range of missions with operating characteristics of cruising speeds at 300 knots and collection speeds at 200 knots, a ceiling of 35K feet AGL, endurance exceeding 9 hours and range of over 2,300 nautical miles. Leidos has recruited, trained, and certified a complete aviation staff capable of conducting worldwide self-deployable/self-sustainable operations from civil and military airfields without any special or unique support equipment.

Contact Information

David Radcliffe (Technical)

Email: [email protected]Sean M. Goodwin (Business)

Email: [email protected] -

At Leidos, we know important work never stops. Our uncompromising focus is on evolving and accelerating readiness, resilience, and strategic modernization. Leidos has nation-scale expertise, working alongside domestic and international organizations and agencies—including the DOD, DISA, and all branches of the U.S. military—to revolutionize and future-proof their capabilities around the world and across domains.

We deliver a holistic Contractor Owned Contractor Operated (COCO) service that includes aircraft, flight operations, maintenance operations, and logistics support. Our latest high-accuracy airborne Intelligence, Surveillance, and Reconnaissance (ISR) capability is the Leidos Special Mission Aircraft– Global 6500 (LSMA – G6500). The LSMA-G6500 is built on a common platform using a commercially derived aircraft and it intuitively integrates military packages that include secure communications (i.e., SATCOM, secure HF), navigation (i.e., TACAN), workstation, mission rack and mission antenna installation. The LSMA-G6500 is worldwide self-deployable/self-sustainable, able to operate from civil and military airfields without any special or unique support equipment. The LSMA-G6500 is capable of carrying up to 6,500 pounds of Mission Equipment Package (MEP) and operations of up to 6,000 NM ferry range, loiter times in excess of 12 hours of unrefueled flight endurance, at altitudes up to 51,000 MSL. The LSMA-G6500 will exceed ten hours of station time after transitioning 500 NM from departure aerodrome.

Contact Information

David Radcliffe (Technical)

Email: [email protected]Sean M. Goodwin (Business)

Email: [email protected] -

At Leidos, we know important work never stops. Our uncompromising focus is on evolving and accelerating readiness, resilience, and strategic modernization. Leidos has nation-scale expertise, working alongside domestic and international organizations and agencies—including the DOD, DISA, and all branches of the U.S. military—to revolutionize and future-proof their capabilities around the world and across domains.

We deliver a holistic Contractor Owned Contractor Operated (COCO) service that includes aircraft, flight operations, maintenance operations, and logistics support. Our latest high-accuracy airborne Intelligence, Surveillance, and Reconnaissance (ISR) capability is the Leidos Special Mission Aircraft– Global Express (LSMA – GE). The LSMA-GE is built on a common platform using a commercially derived aircraft and it intuitively integrates military packages that include secure communications (i.e., secure HF), navigation (i.e., TACAN), work station, mission rack and mission antenna installation. The LSMA-GE is worldwide self-deployable/self-sustainable, able to operate from civil and military airfields without any special or unique support equipment. The LSMA-GE is capable of carrying up to 6,500 pounds of Mission Equipment Package (MEP) and operations of up to 6,000 NM ferry range, loiter times in excess of 12 hours of unrefueled flight endurance, at altitudes up to 51,000 MSL. The LSMA-GE will exceed ten hours of station time after transitioning 500 NM from departure aerodrome.

Contact Information

David Radcliffe (Technical)

Email: [email protected]Sean M. Goodwin (Business)

Email: [email protected] -

At Leidos, we know important work never stops. Our uncompromising focus is on evolving and accelerating readiness, resilience, and strategic modernization. Leidos has nation-scale expertise, working alongside domestic and international organizations and agencies—including the DOD, DISA, and all branches of the U.S. military—to revolutionize and future-proof their capabilities around the world and across domains.

We deliver a holistic Contractor Owned Contractor Operated (COCO) service that includes aircraft, flight operations, maintenance operations, and logistics support. Our latest high-accuracy airborne Intelligence, Surveillance, and Reconnaissance (ISR) capability is the Leidos Special Mission Aircraft (LSMA). The LSMA is built on a common platform using a commercially derived aircraft and it intuitively integrates military packages that include secure communications (i.e., secure UHF/VHF), navigation (i.e., TACAN), and survivability (ASE) for all aircraft.

Contact Information

David Radcliffe (Technical)

Email: [email protected]Sean M. Goodwin (Business)

Email: [email protected] -

Providing implementation, optimization and advisory services to advance McKesson systems for improved outcomes.

-

Part of our comprehensive checkpoint security solutions, Leidos offers a wide variety of metal detectors walk through and handheld that help screeners differentiate between harmless objects and potential threats.

-

Mezzo™, our newest enterprise-ready software platform, was specifically designed to integrate multiple NII data sources into a secure, common platform, providing greater situational awareness for a variety of security applications.

-

MICHELLE has models for both equilibrium flow particle trajectories and initial-value time-dependent beam trajectories. It self-consistently computes the emission and transport of charged particles in the presence of electrostatic and magnetostatic fields. The charged particles contribute to the static fields, and the static fields act on the charged particles. The equilibrium flow particle model is also known as a steady-state static PIC code or a gun code. The time-dependent model is an electrostatic time-domain particle-in-cell (PIC) code.

Applications

Engineers and scientists use MICHELLE to analyze and design a wide variety of electron and ion sources, accelerator beamline components, and vacuum electron device components. The code is used in industry, national laboratories, and academic research institutions. MICHELLE can model devices that range from simple 2-D axisymmetric devices to very complicated 3-D devices, including those with fine geometric features on disparate spatial scales. MICHELLE can model beam formation, beam transport and focusing systems and beam collection.

Features

MICHELLE was developed to be an architecture that hosts multiple Electromagnetic and Electrostatic field solvers with Particle tracking capability for both Time-Dependent and Steady-State. It is based on a Finite-Element Particle-In-Cell formulation employing a conformal mesh to resolve very complex geometries with fine features.

- Computes the self-consistent emission and transport of charged particle streams (rays) in self and external fields, both electric and magnetic.

- Has a variety of emission models including space-charge-limited, temperature-limited and field-emission, an extensive facility for secondary emission, volumetric ion source model, and a charge exchange model.

- Java-based graphical user interface for preparing runs, and a Windows postprocessor for viewing results. The preprocessor interfaces with the powerful ICEM-CFD mesh generator suite.

Benefits

- Employ a multiblock structured grid, an unstructured grid, or both in a multiblock hybrid mesh that best takes advantage of both grid types. This allows MICHELLE to model very complicated geometries and resolve very strong field gradients as necessary. The conformal mesh capability and grid types supported allow disparate feature scales to be captured in the analysis.

- Supports linear and quadratic element shapes and basis functions: triangles and quads in 2-D; tetrahedral, hexahedra, prisms and pyramids in 3-D. The different element shapes allow the user to improve the accuracy of a simulation by choosing the optimum mesh topology for the geometry and physics desired.

- Has two mesh-adaptive particle pushers: a fast Boris-type pusher for structured grids and a unique accurate, reliable pusher for unstructured. The option of different particle pushers allows the user to choose between speed and accuracy.

- Integrated into the sophisticated ANALYST EM design environment and included adaptive mesh refinement and global design optimization.

- Although MICHELLE can run in the Voyager User Environment, it is also available in the ANALYST electromagnetic code user environment, by Simulation Technology & Applied Research (STAR Inc). The ANALYST environment is a powerful design environment that includes CAD, Meshing with Adaptive Mesh Refinement, global parametric optimization available to MICHELLE. It also hosts STAR's parallel finite-element electromagnetic frequency domain codes in eigenvalue and driven-frequency models.

- Can be used to run complicated models with over 5 million tetrahedral elements and many tens of thousands of rays. The robustness of the code to handle small to large mesh sizes in 2-D or 3-D geometries allows the designer to work rapidly to test different possibilities and gain intuition during the research and scoping stages of development. Subsequently, the designer can improve the mesh density as needed to validate the detailed or final designs.

-

ADWS MILES expands force-on-force live training capability and fidelity from infantry-based and armor-based exercises to the inclusion of simulated air defense engagements-ground to air, and air to ground. It provides an adaptable, wireless, tactical engagement and instrumentation system for contemporary air defense weapons manufactured domestically and internationally.

-

Computerized aircraft mission planning system. It provides pilots, mission planners, and evaluators with preflight rehearsal and analysis information for aircraft around the world.

-

The MK-19 Simulator Player Unit simulates the firing and actual effects of an MK-19 in a Multiple Integrated Laser Engagement System (MILES) environment. Like all Leidos TES training systems, the MK-19 Simulator Player supports tough, realistic field training exercises with wireless, lightweight, low-power, laser common components which are interoperable throughout our dismounted and mounted systems.

-

MMADTO™ is a one dimensional, multilayered, laminant absorber design code. It is the material stack optimizer for radar absorbing materials.

Contact Information

Email: [email protected]

-

A self-contained Mobile Data Center available for lease from Leidos for commercial and Government customers to function as a mobile or on-site data center. The Mobile Data Center provides cooling, power, computer racks, and lighting for setting up quick on-site data center operations.

-

Our Memory Unit Tactical Air Crew Training System (MUTACTS) provides quick, accurate, and cost-effective post-flight review and analysis of military aircraft training missions. MUTACTS and its companion product for pre-flight analysis, the Mission Planning System (MPS), are both based on exportable map database technology.

Applications

MUTACTS accurately reconstructs complex training sorties anywhere — without the need for an instrumented range. The system's portability provides tremendous scheduling and location flexibility, and saves range fee expenses. Every flight is recoverable as a training event. Ease-of-use features include simple downloading and state-of-the-art graphics displays of air combat scenarios for pilots, mission planners, and evaluators. This proven system has been in operation since 1997 and has benefited from continuing enhancements to support the latest avionics and weapons systems. The system is currently in use by the United States and several international customers.

Features

- Data can be delivered less than half an hour after landing for post-mission tactical debriefs.

- In-depth, definitive detail from the avionics data stream is available when the information is most useful, providing critical feedback within an optimal recall interval.

- Multiple aircraft can be precisely tracked through aerial maneuvers.

- Captured data is automatically archived for reuse to maximize training at minimum cost.

Benefits

MUTACTS supports post flight debriefing and training for both air-to-air and air-to-ground weapon simulations. Flight reconstruction can accommodate as many as 30 high activity aircraft. Synchronized displays (3-D and 2-D) of both mission data and aircraft cockpit video are shown over high fidelity digital terrain models.

The built-in communications capability enables synchronized debrief between multiple remote sites. In addition, dissimilar aircraft can participate simultaneously. The system accepts data from either external wing-mounted pods or the self-contained avionics in newer aircraft.

-

MUTACTS provides quick, accurate, and cost-effective post-flight review and analysis of military aircraft training missions. It, and its companion product for pre-flight analysis, the Mission Planning System (MPS), are both based on exportable map database technology.

-

Leidos' MV3D checked baggage screening system delivers an unbeatable combination of innovative technology, superior threat detection, reliable performance and cost efficiency. Offering high speed performance securely scans up to 1,800 bags per hour.

-

Neutron Sandwich (NeuSand) is an innovative, flexible neutron detection solution to a critical national security need. It detects neutrons emitted by materials used to make nuclear weapons. Neusand is ideal for detecting smuggled nuclear material at border crossings, airports and ports, and can also be used for nuclear safety.

-

The NCM3 is among the first virtual aviation crew trainers for the rear portion of the CH-47 Chinook and UH-60 Blackhawk aircraft. It enables helicopter crews to train together and improve mission coordination and proficiency prior to deployment.

-

OC2ELOT is an open, non-proprietary framework designed to automate and optimize complex workflows. It integrates heterogenous data, systems, and functional components such as AI/ML and decision aids, transforming data into actionable knowledge. Its open architecture supports seamless integration and replacement of third-party capabilities, enabling mission-specific solutions while optimizing runtime constraints such as compute, time, memory, and fidelity. OC2ELOT is tailorable for diverse use cases including command and control, sensor orchestration, and more.

Key Features

- Architecture: Open, non-proprietary design for rapid development and vendor flexibility; multi-platform support for cloud, on-premise, and edge deployments.

- Performance: Memory-safe programming for security and efficiency; advanced optimization algorithms and high-performance analytics.

- Integration: Multi-level support for data, systems, and functions; compatible with legacy applications; multi-phenomenology data integration for situational awareness.

Applications

- Space Domain Awareness: Real-time tracking of space objects and rapid response to launches.

- Sensor Orchestration: Coordination and dynamic re-tasking of multi-domain sensors.

- Mission Support: Space defense and multi-domain command and control.

Mission Performance

In a space domain awareness scenario, OC2ELOT orchestrated sensors from multiple vendors to track more than 1,000 space objects. When a new launch was detected, it re-planned sensor tasking in less than two seconds while maintaining continuous surveillance of existing objects.

Contact Information

Email: [email protected]

-

This unit, UF-1001 has been selected for the LPD 17 class. The unit takes incoming oily water from the shipboard “Oily Water Separator” and process it via ultrafiltration ceramic membranes to enable overboard discharge of the permeate water (below 15 ppm).

-

OMEGA is a multiscale atmospheric simulation system for advanced, high-resolution weather forecasting and forecasting dosage and hazard levels due to the atmospheric release of aerosols and gases. It has a horizontal grid resolution that ranges from 100 km to 1 km and a vertical resolution that ranges from a few meters to 1 km. OMEGA represents a significant advance in the field of weather prediction. Operational forecast models in current use are scale-specific. Their fixed rectangular grid structure limits the resolution of both the input boundary conditions and the resulting atmospheric simulation. The OMEGA model grid, which is unstructured in the horizontal, adapts to the underlying surface features and can dynamically adapt to atmospheric phenomena as they evolve.

The major advantages of OMEGA over the current state-of-the-art include the ability to resolve the surface terrain down to scales of 1 km and along with that the local perturbations on the larger scale wind field. This local wind field perturbation is of extreme importance in determining the trajectory of an aerosol or gas release or plume. However, in order to calculate this local perturbation, it is important to include all of the physical parameters and processes, which affect the local flow. These include not only the topography, but also the land use, the land/water composition, the vegetation, the soil moisture, the snow cover (if appropriate), and the surface moisture and energy budgets. The inclusion of this additional physics, some of which is only appropriate because of the increased spatial resolution, represents an additional advance in the state-of-the-art.

-

ProVM is a data management tool that captures maintenance actions, material suppliers, and failure rates to deliver actionable intelligence to the warfighter for effective decision-making and enhanced combat readiness as well as improved sustainment, operational reliability, and availability of platforms.

-

PFM is designed to efficiently store bathymetric data and generate various representations of the data ("surfaces") for editing, display, and analysis.

-

Fully CE certified, ProPassage has been ergonomically designed to ensure easy loading and unloading of hand baggage. A simple and effective automated tray return facility increases throughput rates whilst eliminating the need for repetitive and time consuming, manual handling of trays by checkpoint personnel.

-

ProSight™ is an open architecture, scalable and cyber secure software platform that integrates security screening equipment, threat detection algorithms and other third-party data. As a centralized, enterprise management solution, ProSight delivers actionable, real-time data to improve operational efficiencies, increase throughput and reduce costs, and enhances security and threat detection capabilities.

-

Our ProVision 2 is the most widely deployed advanced personnel screener in the world. It quickly screens passengers using safe millimeter wave (MMW) technology to automatically detect concealed objects made of a broad variety of concealed materials – both metallic and non-metallic.

-

The Pro:Vision 3, the newest in our portfolio, is a people screener designed to meet evolving security needs. It uses wide-band frequencies to enable superior levels of detection and throughput while achieving the industry’s lowest false alarm rates.

-

The Pro:Vision CI is a cutting-edge people screening solution designed to address present and future security requirements. Ideal for critical infrastructure applications, it excels in detecting a wide variety of contraband and allows users to adapt to emerging threats in real time.

-

Provides real-time, sub-meter tracking information through a broad range of operational environments, including those without Global Navigation Satellite (GNS) services. The system provides users with precise position data, including end-of-train and track discrimination information.

-

Designed for airports, correctional facilities, freight forwarders and border entry points, Leidos PX conventional X-ray screening systems feature multiple tunnel sizes to accommodate baggage, packages, and palletized freight.

-

Provides real-time collection, discovery and analytics of social media and open-source content data across multiple sources and types. Can be configured for global or targeted collections and custom dashboard analytics visualizations, in an open architecture environment with Deep Learning analytics. Capabilities now integrated with Veracint.

Q-U

-

The Exploranium SRPM-210 advanced radiation portal monitor (RPM) uses our unique passive scanning technology to detect, locate and classify nuclear material in cargo containers, trucks and other vehicles in the normal flow of checkpoint traffic.

-

Sensitive, accurate radiation detection and nuclide identification, in a rugged handheld system for use in the field.

-

RADSIM is a high-fidelity radar simulation capability for flight simulators, unmanned aerial vehicle (UAV) simulators, radar scope interpretation (RSI) training, image analyst training, or mission planning/rehearsal systems.

It can produce a very high-fidelity geo-specific or generic, simulated real-time synthetic aperture radar (SAR), Doppler beam sharpening (DBS), and real beam imagery to less than one-meter resolution.

-

The RailView system is a rugged digital video recorder for locomotives. It continuously records the scene in front of the train whenever the locomotive is in motion, along with audio, speed and other information — automatically, with no human intervention required.

-

The RC-12X Cockpit Procedural Trainer provides procedural, sustainment, and annual training simulation solutions for the RC-12X and Hawker Beechcraft King Air 350ER aircraft, enabling pilots and co-pilots to train without leaving the mission.

-

At Leidos, we know important work never stops. Our uncompromising focus is on evolving and accelerating readiness, resilience, and strategic modernization. Leidos has national-scale expertise, working alongside domestic and international organizations and agencies—including the DOD, DISA, and all branches of the U.S. military—to revolutionize and future-proof capabilities around the world and across domains.

The Leidos Retractable ISR System is a retractable camera mount system optimized to improve Aerial Intelligence, Surveillance, and Reconnaissance (ISR) systems’ operational capabilities.

The operational benefits of the Leidos Retractable ISR System include:

- Increased mission endurance

- Decreased operational visual signature

- Increased protection of ISR sensors from FOD

The Retractable ISR System supports the WESCAM MX™-20 Electro-Optical Infrared (EO/IR) camera and can be upgraded to host other MX products.

Contact Information

Mike Hile (Technical)

Phone: 719-474-8143

Email: [email protected]Catherine McIntyre (Business)

Phone: 703-200-1329

Email: [email protected] -

Reveal CT-80DR+ Baggage Inspection System

The Reveal CT-80DR+ combines powerful dual-energy X-ray CT imaging with proven explosives-detection technology to provide outstanding threat-detection capabilities with a very low false-alarm rate. With its high performance, compact size and low cost, the CT-80DR+ is a highly effective and economical security solution for airports and other passenger facilities.

-

The RTR-4® system is designed to help law enforcement, military, customs and security personnel search for explosives, weapons, narcotics and other contraband. The system can reveal the contents of parcels, baggage, boxes and crates, vehicle tires and body panels, aircraft walls and wings, building walls, and many other targets.

Features

The RTR-4 system consists of a lightweight, compact x-ray source and imaging unit that are positioned on opposite sides of the target object, plus a standard notebook computer for controlling the system and analyzing images. The control computer is connected to the imager by an Ethernet cable or optional wireless connection.

The standard RTR-4 system includes the following components:

- X-ray source: The standard source can penetrate more than 25mm (1 inch) of steel. A more powerful source is also available.

- Imager: The standard imaging unit provides high-resolution images up to 20 x 25cm (8 x 10 in). A larger imager with an area of 40 x 56 cm (16 x 22 in) is also available.

- Control computer: A standard notebook computer provides system control and image-analysis functions. A rugged Toughbook® computer is also available. The computer is supplied with our RTR-4 database and image-analysis software, available in many languages.

-

Fast, online x-ray imaging for parcels, baggage, vehicles and walls, in a rugged system designed for use in the field.

-

SABER is used for processing, editing, updating, viewing and analyzing hydrographic survey data. Leidos developed SABER to be one of the most flexible, robust data processing tools in the industry. The software was designed to efficiently and smoothly archive, display and process large data volumes associated with hydrographic surveys.

-

Sea Dart™ is a high-performance unmanned underwater vehicle built for versatility. Fast, flexible and mission-ready, it’s designed to give the U.S. Navy and commercial customers a decisive edge where it matters most.

With a price point that's 80-90% less than comparable systems, Sea Dart makes undersea autonomy more accessible and scalable.

-

An Offshore Supply Vessel available for lease from Leidos, for commercial and Government customers to perform survey missions, launch and recover equipment and to perform science and technology research related to autonomy. ITAR constraints would apply to both commercial and government applications.

-

Our dechlorinator unit for surface ships operates with permanently installed seawater biofouling chlorine injection systems used to service high volume A/C condensers and firemain systems. Our dechlorinator unit for submarines operates with the Topside Chlorinator to ensure zero discharge of chlorine.

-

Service Integration and Management (SIAM™) has proven to be one of the best solutions to address the increased popularity with Multi-sourced ICT environments knows as “TowerModels”. By supplying the ‘mortar’ that binds the individual ‘bricks’ in the Tower Model, SIAM ensures that the range of constituent parts, whether outsourced or delivered internally, fit together to provide a single, effective ICT service to the user

Applications

SIAM can be used to evaluate the impact of each factor in a range of situations, from national security planning to corporate decision-making. Uses include:

- Analyzing a political event

- Assessing a new advertising campaign

- Projecting variations in a financial plan over time.

- Collaborate Across Disciplines

- Analyze Problem Subcomponents.

- Examine Competing Viewpoints/Different Potential Outcomes

Features

- Intuitive and user-friendly interface

- Automated assessment capability

- Independent evaluation of factors/influences

- Understanding of overall impact and interrelationships

- Operates on Windows 2000 and Windows XP operating systems

- Minimum requirements are 2.4GHz Pentium IV with 512MB RAM and CD-ROM

Causeway™, SIAM's "sister application", is available for export and can be localized to different languages. A Service Support Agreement (SSA) can be purchased which includes upgrades. Training and modeling services are also available.

Benefits

SIAM encourages the user to consider and track the impact of all issues, events, perceptions, and other factors which are believed to be of some significance. By analyzing all relevant issues, the user can make the most informed decision possible. Automated assessment tools allow the user to evaluate the importance of uncontrolled variables, and adjust decisions to incorporate major developments and changes to the situation or information updates available to the user. With its user-friendly graphical structure and automated evaluation functions, SIAM encourages a more detailed level of thinking than is sometimes possible by intuition alone. Once identified, these detailed issues and relationships can be assessed for their importance within the larger picture.

-

SIG2D™ is a surface integral computer code for radar cross section analysis of objects that exhibit translational symmetry. It is designed for problems which can readily be characterized as a combination of piecewise homogeneous bulk materials, metal surfaces, impedance boundary surfaces, and shunt impedance surfaces.

Contact Information

Email: [email protected]

-

SIGLBC™ rigorously computes the RCS of systems/sub-systems and in-situ antenna patterns using generalized surface integral equations. It was developed with focus on the RCS designer. The formulation is selected to be robust in an environment of complex 3D shapes, optimization and fast incremental updates have been a paramount concern from the onset, and the code has been engineered for easy implementation on high speed platforms.

Contact Information

Email: [email protected]

-

The deployment of Mach-SmartBRS offers improved baggage reconciliation operations for both small, large and more complex airports plus tangible improvements in passenger satisfaction ratings.

-

To assist utilities with grid modernization, Leidos developed Smart Grid Select (SGS), a full-service, turnkey solution with unmatched solutions for every stage of smart grid deployment.

-

Leidos-Pittsburgh worked with NSWC on development of 4 unique machines for Surface Shipboard Solid Waste Processing. Leidos-Pittsburgh continues their OEM role in configuration control and design agent for equipment fleet upgrades. Machines are the Large Pulper (paper/food waste); Plastic Waste Processor or Compress Melt Unit; Mod 1 Shredder (processes Metal/Glass or Plastics); and the Small Pulper (paper/food waste). Each machine has its specific auxiliary equipment (Electrical Panel, Main Switch, Mini-Aux Unit, etc). Every surface ship dependent on crew size contains a suite of equipment that is specific based on the needs of the ship class.

-

Sterling Integration develops, designs and manufactures cost-effective information technology solutions for military and industrial applications. Our innovative concepts for rugged and reliable systems are built to withstand shock, vibration, moisture, dirt and dust. Whether aboard a ship, aircraft, vehicle, or land-based, our line of commercial off-the-shelf products are designed to withstand the harshest environments.

-

The Tactical Data Links (TDL) toolset consists of a unique set of software applications to support the engineering testing cycle for TDLs, from requirements capture (eSMART), terminal control, monitoring and recording (PUMA), real-time message analysis (CIVET), post mission analysis (MANDRIL) and overall through-life TDL requirements management (eSMART).

-

Provides noncombat vehicles and targets with high-fidelity detection systems for real-time casualty assessment.

A range of products meet live training needs — from basic Multiple Integrated Laser Engagement System (MILES) components to the most recent MILES variant, and exciting, emerging efforts like the Operational Test — Tactical Engagement System (OT-TES) and geometric-bearing (GB) systems.

-

The TeraText® suite of products includes a number of technologies for solving complex archival, search, and text-oriented problems.

-

TRAPS is a rapidly deployable, low-cost, persistent, deep-ocean sensor system for long-range passive Anti-Submarine Warfare with nodes deployable and effective across a variable duration based upon operational usage.

-

TransVM is an integrated toolset designed to manage shipment activity from order creation to final delivery in a true exception-based environment. Internal shipping departments and 3rd-party logistics providers use TransVM to effectively measure and control end-to-end logistics, and synchronize their supply-chain. Users wield a powerful suite of functionality to gain visibility of shipments, manage shipping events, perform carrier selection, shipment rating, analysis and reporting.

-

The Urbana™ toolkit simulates wireless propagation and near field radar sensors in complex environments. The underlying ray-tracing physics engine aggregates Physical Optics, Geometric Optics, and Diffraction Physics to produce a high-fidelity simulation.

Applications

- Urban Propagation — The Urbana toolkit provides wireless system planners with a powerful tool to simulate propagation in outdoor rural and urban settings.

- Indoor/Outdoor Propagation — The Urbana toolkit ray tracing engine can account for the complex, cascading multi-bounce effects introduced by multiple walls and other partially penetrable boundaries in an Indoor/Outdoor environment.

- Collision Avoidance Radar — The Urbana toolkit also features a high-fidelity radar signal scattering solution specifically designed to handle complex scenes with numerous scattering features generating radar returns, such as automotive collision radar applications.

- Antenna Studies — Urbana toolkit allows users to study antenna designs and locations to determine the optimal configuration for a particular application.

Features

Key inputs to the Urbana code:

- CAD facet models for terrain, buildings, and other features

- Surface material properties (e.g., concrete, earth, glass, dielectrics, etc.)

- Placement, strength, and vector polarized antenna patterns of transmitter and receivers

- For wireless applications, descriptions of coverage regions that conform to the terrain and buildings in the scene (these are automatically built by Urbana)

Key outputs:

- Composite field level at each receiver or coverage region sampling point

- Angle of arrival, polarized strength, and delay of each arriving signal

Benefits

The Urbana toolkit models wireless and radar systems exhibiting time, frequency, spatial, and field polarization dependence. For wide-band systems, it allows the user to understand the frequency dispersive properties of a channel introduced by realistic materials.

Urbana's powerful modeling tools allow engineers to analyze spatial dependencies that arise from the physical complexity of the environment. Its interface reveals regions of relatively strong or weak signal levels and provides a diagnostic tool for interpreting the results.

Contact Information

Email: [email protected]

V-Z

-

Unified software solution that provides convenient online tools to manage vaccination events, including scheduling, consent, privacy disclosures, safety questionnaires, and electronic certificates of vaccination.

-

VACIS systems scan cargo containers, trucks, cars and other vehicles to help authorities search for weapons, nuclear material, narcotics, undeclared goods and other contraband at cargo terminals, border crossings, military facilities and other checkpoints

- VACIS® MLX Mobile High-Energy Inspection System

- VACIS® M6500 Mobile Inspection System

- VACIS® IP6500 FullScan Integrated Cargo Inspection System

- VACIS® XPL Passenger Vehicle Scanning System

- VACIS® IR6500 Integrated X-ray Railcar Inspection System

-

A Sharepoint application, created by Leidos, to enhance usability.

-

Veracint is a mission-focused data collection and exploitation platform that monitors and analyzes rapidly changing Publicly Available Information. This platform integrates customized collectors and machine learning analytics to augment and enrich the data into actionable intelligence for a variety of use cases. Veracint has integrated PXP and DDAM capabilities.

-

WBS is an in-line system that digitally pre-processes the co-channel RF environment ahead of the cellular surveillance receiver, enabling it to reliably demodulate the cell traffic in a target area. WBS significantly improves the surveillance and target detection range, integrates directly with existing cellular surveillance receivers.

-

The WITS is software-adaptable to support the full range of tracked and wheeled logistics, utility, and light armored vehicles in service today. The WITS is easy to mount on a variety of vehicles and targets making it one of the most adaptable and flexible Multiple Integrated Laser Engagement System (MILES) target products available today.

Features

- Player ID and zone of impact decoding

- Infrared data association (IrDA) port for external reprogrammability

- Built-in Global Positioning System (GPS) receiver

- 80 externally programmable vehicle types and PK tables